SOCOTEC developed innovative structural engineering solutions for the Glories Tower, solving the technical challenges of this iconic building in Barcelona through a unique system of double cylinders and slabs without pillars, culminating in a glass and steel dome.

Technical Sheet:

- Client: Jean Nouvel and b720 Architects

- Location: Barcelona, Spain

- Year: 2002-2004

- Architects: Jean Nouvel and b720 Architects

- Photo property: ©SOCOTEC Spain & Rafael Vargas

An architectural landmark with unique structural challenges

The Glories Tower, with its 142 metres high, represents one of the most emblematic elements of the Barcelona skyline. This unique project combines avant-garde aesthetics with revolutionary structural engineering solutions. The building has an elliptical geometry plan with main axes of 39.50 and 35.50 meters, forming an imposing cylindrical body that closes in on itself at the top.

The project was divided into two major structural challenges: the construction of four basement levels reaching 17 meters deep, and the erection of the tower itself with its 33 floors above ground, each with particular structural characteristics that demanded precise and sophisticated structural engineering solutions.

Talk to our experts

FOUNDATIONS

Structural engineering of the Glories Tower: The challenge of the foundation

The presence of the water table at about 10 metres below ground level was a fundamental challenge for the structural engineering of the Glories Tower.

The bottom of the stope was about 8 metres below this level, which decisively conditioned the design of the containment structures. These were designed not only with criteria of stability and resistance, but also with the intention of forming a vessel as watertight as possible.

Deep diaphragm walls were chosen, provisionally tied to the ground by means of anchors. Considering that the dead weight of the construction in the provisional phase was much lower than the upward pressure, an underpressure slab anchored to the ground was designed by means of screen modules that worked at negative friction, balancing the underpressure during construction and transmitting the loads to the ground once the building was completed.

The presence of the water table at about 10 metres below ground level was a fundamental challenge for the structural engineering of the Glories Tower.

The bottom of the stope was about 8 metres below this level, which decisively conditioned the design of the containment structures. These were designed not only with criteria of stability and resistance, but also with the intention of forming a vessel as watertight as possible.

Deep diaphragm walls were chosen, provisionally tied to the ground by means of anchors. Considering that the dead weight of the construction in the provisional phase was much lower than the upward pressure, an underpressure slab anchored to the ground was designed by means of screen modules that worked at negative friction, balancing the underpressure during construction and transmitting the loads to the ground once the building was completed.

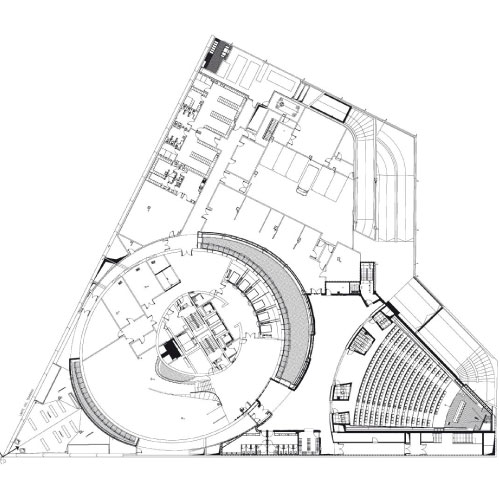

Innovation in Structural Engineering of basements

The structure of the basements was configured with a conventional typology of 8 meter spans, resolved with reinforced concrete slabs of 30 cm in depth. A notable singularity was the location of the auditorium, which required a special pillarless structure in a dimensionally limited space.

The structural engineering solution for this space was a "sandwich" slab with double curvature of reinforced concrete in situ, lightened by expanded polystyrene coffers, forming a laminar geometry in accordance with the landscaping of the architectural project.

DOUBLE CYLINDER

Structural engineering of the Glories Tower: Double cylinder system

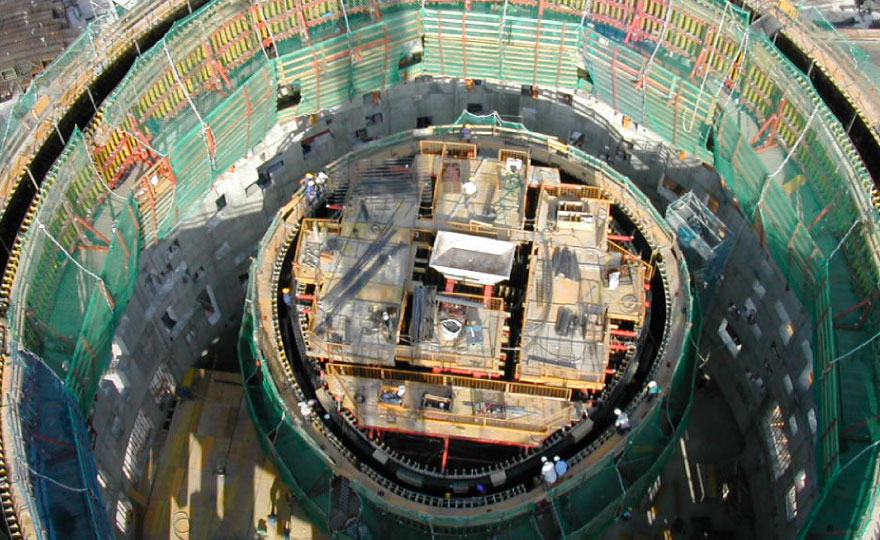

The true uniqueness of the structural engineering of the Glories Tower lies in its vertical system, resolved by means of two reinforced concrete cylinders.

The outer cylinder functions as a perimeter wall while the inner one, non-concentric, forms the structural core. Both elements were built using the climbing formwork technique.

The slabs, with metal frameworks, rest on these two vertical elements without any intermediate pillars, creating open spaces of up to 500 m³. This structural engineering solution made it possible to achieve spans of up to 15 meters between the core and the exterior wall, and transverse spans of close to 35 meters, providing extraordinary openness to the floors.

The true uniqueness of the structural engineering of the Glories Tower lies in its vertical system, resolved by means of two reinforced concrete cylinders.

The outer cylinder functions as a perimeter wall while the inner one, non-concentric, forms the structural core. Both elements were built using the climbing formwork technique.

The slabs, with metal frameworks, rest on these two vertical elements without any intermediate pillars, creating open spaces of up to 500 m³. This structural engineering solution made it possible to achieve spans of up to 15 meters between the core and the exterior wall, and transverse spans of close to 35 meters, providing extraordinary openness to the floors.

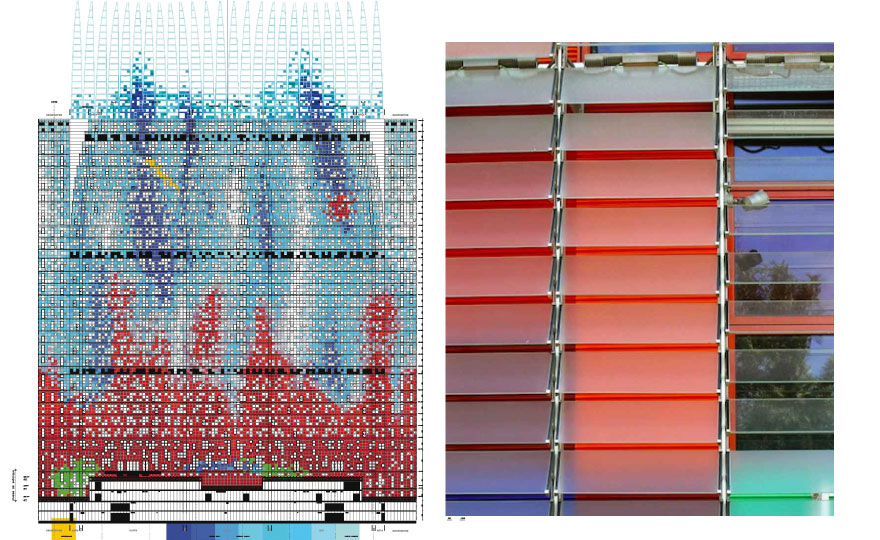

Technical challenges in façade structural engineering

The exterior wall has a decisive singularity derived from the design of the openings. It was based on a theoretical grid of 92×92 cm that modulates the entire façade, arranging the openings in an apparently random way. This pattern does not allow the approach of conventional gantries nor does it guarantee the vertical transmission of loads to the foundation.

To solve this structural engineering challenge, the wall thickness is variable according to height, maintaining a constant thickness within each floor. From 76 meters, the wall begins to slope forming a polygonal curve, which added complexity to the structural design.

Structural engineering of the Glories Tower: Solutions for slabs without columns

The horizontal structure of the slabs was designed under specific structural engineering criteria:

- Achieving the lowest possible weight

- Adaptability to plant networks

- Creating pillarless plants

- Use of simple construction procedures

- Maximum prefabrication of elements

The solution adopted was a mixed structure with large Voit beams arranged every 3 meters and slabs of collaborating corrugated sheet metal. This framework defines two orthogonal directions parallel to the main axes of the ellipse that forms the outer wall.

CANTILEVER AND DOME

Advanced Structural Engineering: Cantilever and Dome Plants

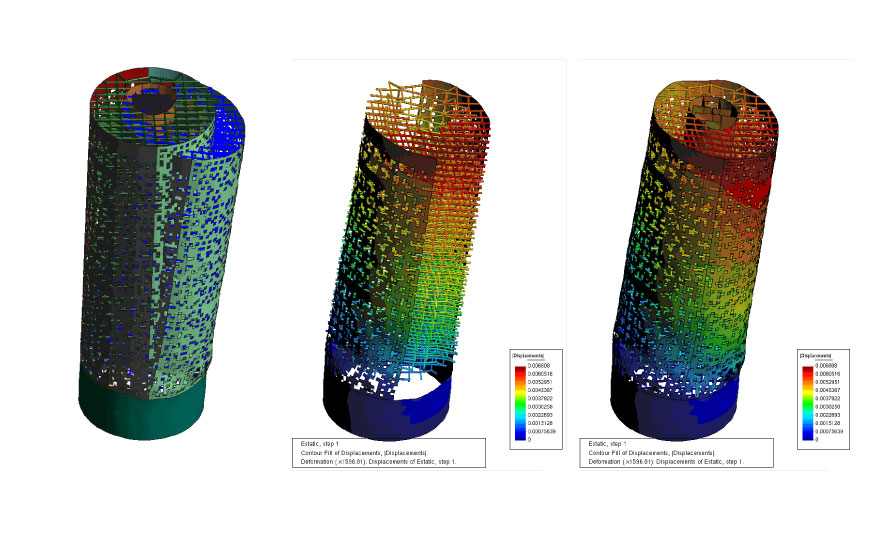

The top six floors of the Glories Tower represent a display of structural engineering. From a height of 110 metres, these slabs are supported by cantilevers from the inner core using post-tensioning techniques, without contacting the outer perimeter at any point. A post-tensioned slab with variable and decreasing depth was used towards the outside, from 50 to 25 cm.

The culmination of the structural engineering of the Glories Tower is its spectacular dome, resolved by a metal structure defined by 26 meridians and 19 parallels. This grid supports the joinery frames of the double glazing, presenting the additional challenge of maintaining low deformability without using triangulation braces in any of the frames.

The top six floors of the Glories Tower represent a display of structural engineering. From a height of 110 metres, these slabs are supported by cantilevers from the inner core using post-tensioning techniques, without contacting the outer perimeter at any point. A post-tensioned slab with variable and decreasing depth was used towards the outside, from 50 to 25 cm.

The culmination of the structural engineering of the Glories Tower is its spectacular dome, resolved by a metal structure defined by 26 meridians and 19 parallels. This grid supports the joinery frames of the double glazing, presenting the additional challenge of maintaining low deformability without using triangulation braces in any of the frames.

SOCOTEC's expertise in structural engineering of unique buildings

SOCOTEC has established itself as a benchmark in structural engineering for highly complex buildings. Our ability to solve the most challenging structural challenges has allowed us to collaborate with internationally renowned architects such as Jean Nouvel and b720 Architects on this landmark project.

Our structural engineering team transforms the boldest architectural concepts into technically feasible realities, providing innovative solutions that balance safety, functionality and aesthetics. In each project, such as the Glories Tower, we demonstrate our ability to overcome technical limits, turning ambitious architectural visions into solid and lasting structures.