- Client: ADIF

- Location: Valencia

- Year: 2023-2025

Talk to our experts

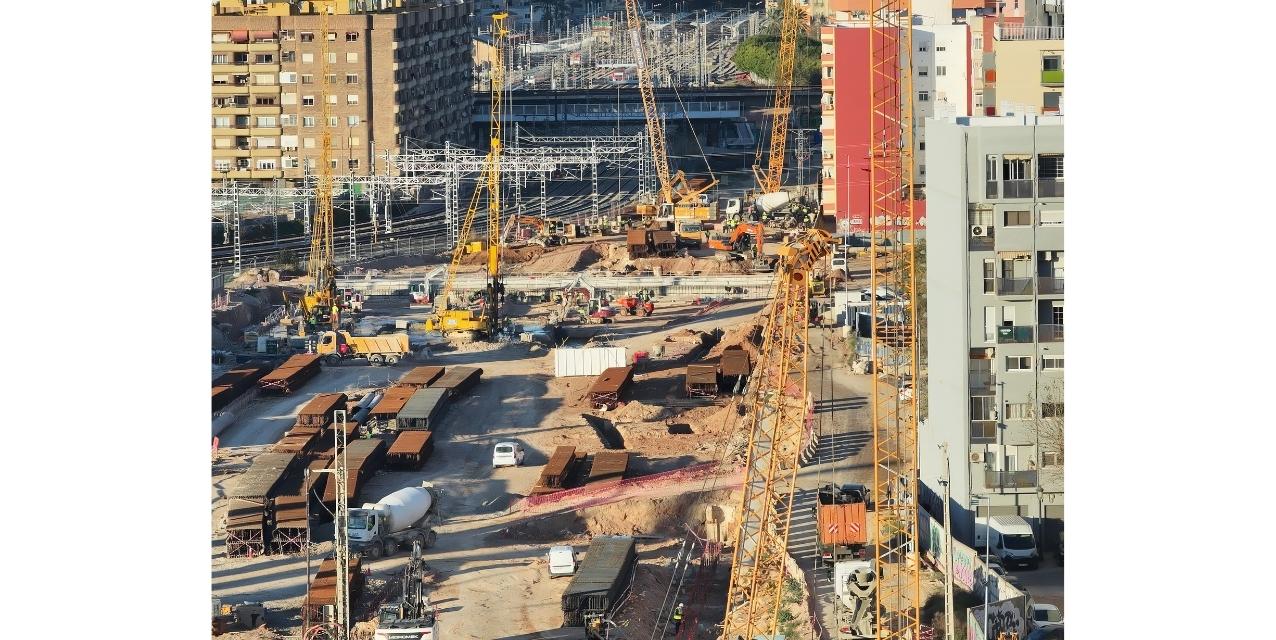

SOCOTEC is participating in one of Spain's most ambitious and strategic infrastructure projects: the Valencia Railway Access.

This project, managed by ADIF, will transform the city’s arterial rail network, enabling the Mediterranean Corridor and High-Speed rail to reach the Estació del Nord, while eliminating the historic 'dead-end' (stub-end) track system."

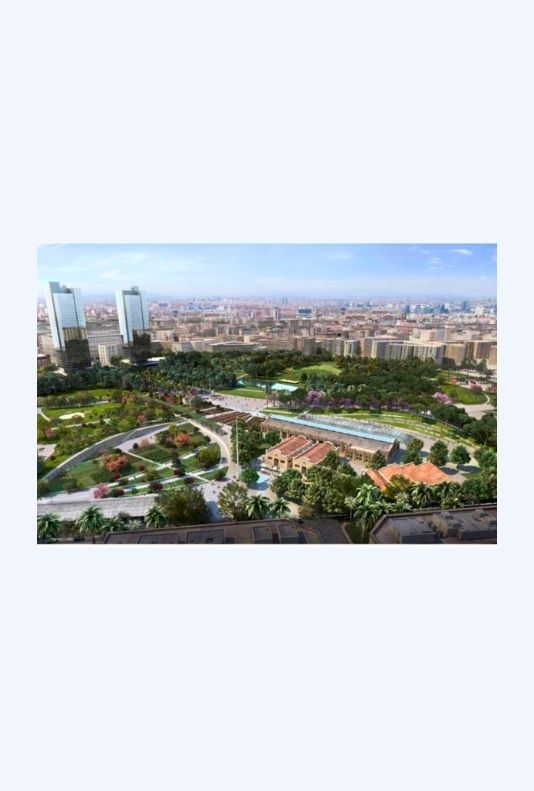

With an investment of nearly 500 million euros and an execution timeline extending until 2028, the project will reclaim a vast surface area to create the future García Lorca Promenade and Central Park, definitively integrating the railway into the city’s urban fabric.

SOCOTEC’s Role

A Guarantee of Quality and Precision Within a highly complex technical environment, SOCOTEC is deploying a comprehensive range of services, including:

Technical Challenges: Innovation at Every Phase

The construction of the channel, which takes place at depths where the water table is found just 5 meters below the surface, has required high-level engineering solutions:

Critical Geotechnics: Execution of low-headroom diaphragm walls under existing bridges and jet grouting techniques for plug sealing in heterogeneous soils, with rigorous controls over diameter and reach.

High-Precision Concreting: Use of self-compacting concrete (SCC) in slabs with high reinforcement density and management of mass concrete pours, strictly controlling temperatures and plant cooling processes.

Dynamic Load Testing: Performance of tests on the slab while in service, utilizing existing rail traffic to ensure structural safety and integrity."

Digitalization and Real-Time Monitoring

Source ADIF

To ensure execution precision and guarantee the absolute integrity of surrounding structures, we have integrated an ecosystem of cutting-edge technologies into the project, allowing for constant, preventive monitoring:

Jean Lutz Guidance and Control Systems: Using high-precision sensors installed directly on the construction machinery, we monitor critical parameters in real-time to guarantee exact verticality during the execution of diaphragm walls and jet grouting bores. This level of digital control ensures the infrastructure adheres millimetrically to the original design, minimizing any deviation in heterogeneous soils.

Smart Instrumentation and Structural Monitoring: We have deployed an advanced network of sensors and thermocouples remotely connected to our digital platforms. This system provides a real-time data flow regarding the stability of nearby buildings and the thermal behavior of mass concrete pours. Through this continuous monitoring, we can proactively manage concrete curing and detect even the slightest structural movements, ensuring a safe coexistence between the scale of the works and the urban environment.

A Reference Project for

Circular Economy and Sustainability

This project not only redefines railway transport efficiency along the Mediterranean Corridor but also stands as a pioneering industry benchmark for its ability to integrate large-scale engineering with absolute respect for the environment. Under a responsible management model, the Valencia Access Channel demonstrates that critical infrastructure can be executed while minimizing environmental impact through three strategic pillars:

Responsible and Circular Water Management: Instead of treating groundwater from the water table as excavation waste, a recovery system has been implemented for industrial use. This water is directly reused on-site for the production of concrete, plastic mortar, and bentonite, optimizing water resource consumption. Furthermore, the surplus is managed through a community-based approach, being discharged into local irrigation channels (acequias) to meet the needs of local farmers, thus returning the resource to the local productive ecosystem.

Driving the Circular Economy: The project is firmly committed to waste recovery by transforming demolished concrete into new resources. These materials are processed and reused as structural subgrade layers within the infrastructure itself, drastically reducing the extraction of virgin aggregates and decreasing the volume of debris sent to landfills, effectively closing the construction material life cycle.

Commitment to Active Decarbonization: To reduce the carbon footprint associated with heavy machinery, high-efficiency power generators fueled entirely by HVO (Hydrotreated Vegetable Oil) diesel have been implemented. This renewable fuel technology enables a 95% reduction in CO2 emissions during the execution process, setting a sustainability standard that places this project at the forefront of green infrastructure in Spain.

This project not only redefines railway transport efficiency along the Mediterranean Corridor but also stands as a pioneering industry benchmark for its ability to integrate large-scale engineering with absolute respect for the environment. Under a responsible management model, the Valencia Access Channel demonstrates that critical infrastructure can be executed while minimizing environmental impact through three strategic pillars:

Responsible and Circular Water Management: Instead of treating groundwater from the water table as excavation waste, a recovery system has been implemented for industrial use. This water is directly reused on-site for the production of concrete, plastic mortar, and bentonite, optimizing water resource consumption. Furthermore, the surplus is managed through a community-based approach, being discharged into local irrigation channels (acequias) to meet the needs of local farmers, thus returning the resource to the local productive ecosystem.

Driving the Circular Economy: The project is firmly committed to waste recovery by transforming demolished concrete into new resources. These materials are processed and reused as structural subgrade layers within the infrastructure itself, drastically reducing the extraction of virgin aggregates and decreasing the volume of debris sent to landfills, effectively closing the construction material life cycle.

Commitment to Active Decarbonization: To reduce the carbon footprint associated with heavy machinery, high-efficiency power generators fueled entirely by HVO (Hydrotreated Vegetable Oil) diesel have been implemented. This renewable fuel technology enables a 95% reduction in CO2 emissions during the execution process, setting a sustainability standard that places this project at the forefront of green infrastructure in Spain.

Our comprehensive involvement throughout the nine construction phases of the project is the ultimate guarantee of rigor and operational excellence. This continuous support allows us to ensure that every kilometer of track, every foundation, and every structure executed strictly complies with the most demanding international standards for safety and durability.

From the initial stages of new building work and complex civil engineering to the final finishes that will enable the definitive urban integration of the infrastructure, the SOCOTEC Intercontrol team deploys its full analytical capacity and on-site expertise. We do not limit ourselves to supervision; we provide the technical solvency and strategic vision necessary to overcome the geophysical challenges of the environment, transforming today’s obstacles into the solid foundations of the cities of the future.

How do you underground a city?

Discover how SOCOTEC Intercontrol leads geotechnics and quality control for the new Valencia Railway Access