Assesses the integrity of infrastructures or structural buildings without damaging or altering them.

We use state-of-the-art technologies to perform accurate diagnostics that ensure the safety and performance of equipment and infrastructure throughout its lifecycle.

What is Non-Destructive Testing?

A Non-Destructive Testing is an inspection procedure that allows the structure, properties and possible defects of a material to be evaluated without affecting its functionality. It is used in critical sectors such as construction, shipbuilding, energy and the manufacture of industrial goods to guarantee the safety and durability of infrastructures.

Objectives of Non-Destructive Testing

The main objective of NDT is to detect defects in materials or structures, assess their condition without compromising their functionality and foresee possible failures. This is crucial to prevent accidents, optimize maintenance and extend the life of the facilities.

- Detect internal and superficial defects.

- Evaluate the quality of welds and materials.

- Prevent structural failures.

- Comply with international safety regulations.

- Optimize costs and minimize risks.

Talk to our experts

What types of Non-Destructive Testing does SOCOTEC perform?

At SOCOTEC, we offer different types of Non-Destructive Testing for different industrial sectors. Prominent methods include:

SOCOTEC: Your Non-Destructive Testing Company

At SOCOTEC, we have the experience and technology to ensure reliable results in the inspection of materials and structures. Our highly qualified team works under ISO 9712 and ASNT certifications.

Not only do we perform conventional Non-Destructive Testing, but we also have Advanced Non-Destructive Testing that includes techniques such as:

- Ultrasonic Phased Array

- Short, medium and long range Guided Waves (GWT)

- Magnetic Flux Leakage (MFL)

In addition, we offer robotic inspections both underwater (ROV) and aerial (DRONE), using high-tech equipment to access the most complex areas.

How is Non-Destructive Testing performed?

Non-Destructive Testing is carried out by applying different techniques, all of them based on advanced scientific principles. The process usually includes preparing the equipment, running the tests, and then interpreting the results. Our highly qualified and certified team ensures that each test meets the most demanding regulations, guaranteeing reliable and accurate results.

Shipbuilding Industry

We carry out advanced inspections in naval structures, ensuring the integrity of vessels and offshore platforms, with IACS certifications and ISO 9712 & SNT TC 1A standards. The techniques applied include:

- Visual Inspection (VT)

- Magnetic Particles (MT)

- Penetrating Liquids (PT)

- Ultrasound (UT)

- Vacuum Box (VB)

- Ultrasonic tightness

- Chain Calibration

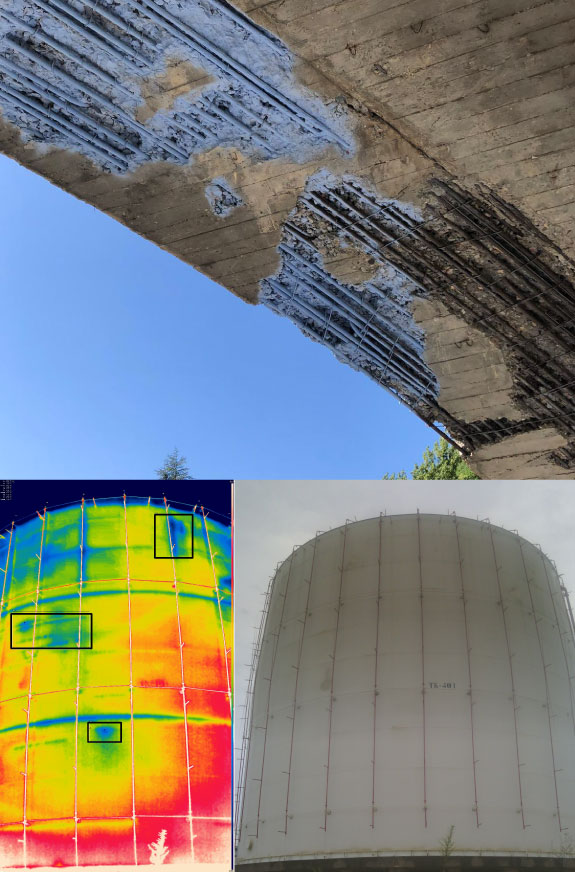

Oil&Gas Infrastructures

We apply conventional and advanced NDT to ensure the reliability and durability of critical infrastructures:

- Conventional and advanced testing (ISO 9712:2012 and ASNT)

- Coating Inspection and Thermography

- Ultrasonic Phased Array

- Robotic inspections (ROV, DRONE, Crawler)

Infrastructure and Civil Works

We perform inspections on bridges, buildings, and concrete structures, using techniques such as sclerometric rebound index testing and ultrasound to assess their structural condition:

- Concrete Structure Inspection

- Strength and durability tests

- Quality control in building and civil works

Instalaciones Fotovoltaicas en Cubierta

En zonas con vientos superiores a 90 km/h, las placas solares pueden generar fuerzas de succión críticas que comprometan la seguridad de la cubierta.

- Para evitar fallos estructurales, SOCOTEC realiza Ensayos de Tracción (Pull-Out Tests) in situ, validando la resistencia real de los anclajes y simulando las condiciones de presión más desfavorables bajo estándares de máxima seguridad

Standards and Procedures for Non-Destructive Testing

SOCOTEC strictly follows international regulations for each type of Non-Destructive Testing, ensuring compliance with best practices and safety standards. Some of the main standards we apply include:

- ISO 9712 (NDT Personnel Certification)

- ASNT (American Society for Non-Destructive Testing)

- API (Inspection in the Oil and Gas Industry)

Experts in Non-Destructive Testing

The SOCOTEC team consists of certified engineers and technicians, constantly trained in the latest testing technologies and ensuring an innovative approach in each project.

Our success is evidenced in emblematic projects such as the Extension of the Rande Bridge, where we apply the following non-destructive tests: Visual Inspection, Magnetic Particles, Penetrating Liquids and advanced Ultrasonic technology.

If you need more information or would like to request a consultation for your projects, please do not hesitate to contact us.

Our team of experts will be happy to help you optimize the integrity of your assets.